What polarity is TIG welding? This question lies at the heart of understanding the intricacies of this specialized welding technique. TIG welding, also known as Tungsten Inert Gas welding, offers unparalleled precision and control, making it a popular choice for welding thin metals, intricate components, and high-quality welds.

In this comprehensive guide, we delve into the world of TIG welding polarity, exploring its types, effects on weld quality, and practical applications.

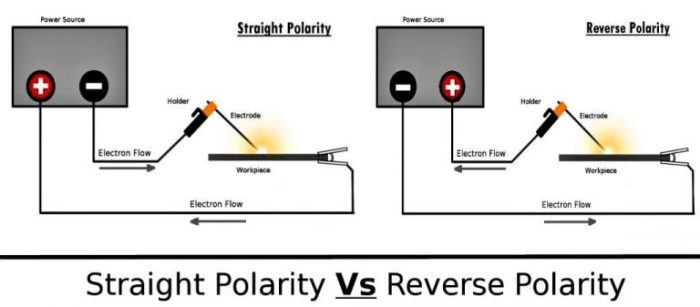

TIG welding involves using a non-consumable tungsten electrode to create an arc between the workpiece and the welding torch. The polarity of this electrical circuit, whether direct current electrode negative (DCEN) or direct current electrode positive (DCEP), plays a crucial role in determining the characteristics of the weld.

Definition of Tig Welding

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), is an arc welding process that uses a non-consumable tungsten electrode to create an arc between the electrode and the metal workpiece. The welding area is protected from atmospheric contamination by an inert gas, usually argon or helium.

TIG welding is a versatile process that can be used to weld a wide variety of metals, including aluminum, steel, stainless steel, and titanium. It is also used in a variety of applications, including aerospace, automotive, and medical.

Equipment and Materials

The basic equipment required for TIG welding includes a welding power source, a TIG torch, a tungsten electrode, and an inert gas supply. The welding power source provides the electrical current that creates the arc. The TIG torch is a hand-held device that holds the tungsten electrode and directs the inert gas to the welding area.

The tungsten electrode is a non-consumable electrode that does not melt during welding. The inert gas protects the welding area from atmospheric contamination.

In addition to the basic equipment, a variety of other materials may be used in TIG welding, including filler metal, flux, and shielding gas.

Types of Polarity in TIG Welding

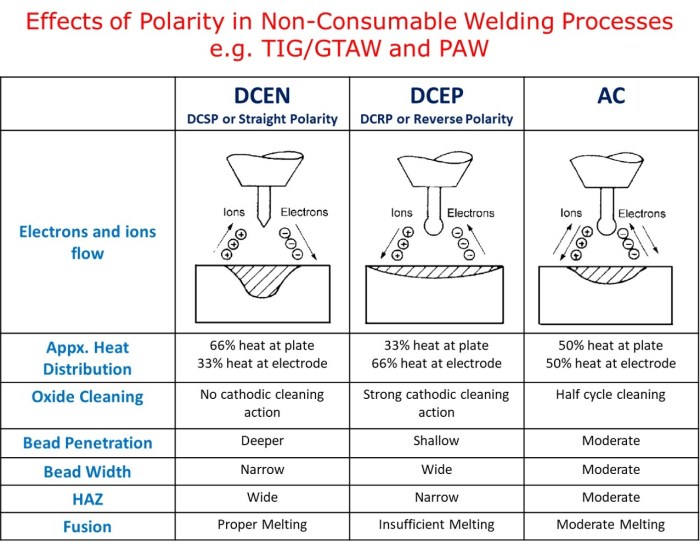

TIG welding employs two types of polarity: direct current electrode negative (DCEN) and direct current electrode positive (DCEP). Each polarity offers unique advantages and drawbacks.

DCEN (Direct Current Electrode Negative)

In DCEN, the electrode is negatively charged while the workpiece is positively charged. This polarity is preferred for welding thin materials as it produces a concentrated arc that minimizes heat input and reduces the risk of burn-through.

TIG welding polarity refers to the electrical connection between the welding torch and the workpiece. In DC welding, the torch can be either positive (DCEN) or negative (DCEP). Just like an advocate of a lawless state , DCEN polarity creates a more focused and hotter arc, making it ideal for welding thin materials.

Conversely, DCEP polarity results in a wider and cooler arc, which is better suited for thicker materials.

Advantages:

- Narrower weld bead

- Reduced heat input

- Less distortion

Disadvantages:

- Limited penetration

- May produce porosity in thicker materials

DCEP (Direct Current Electrode Positive)

In DCEP, the electrode is positively charged while the workpiece is negatively charged. This polarity provides deeper penetration and is suitable for welding thicker materials.

Advantages:

- Deeper penetration

- Wider weld bead

- Reduced porosity

Disadvantages:

- Higher heat input

- Increased risk of burn-through

- More distortion

Effects of Polarity on Weld Quality

Polarity significantly influences the characteristics of the weld, including the depth of penetration, bead shape, and spatter.

Depth of Penetration

In DCEN (Direct Current Electrode Negative), the electrons flow from the electrode to the workpiece, resulting in a higher concentration of heat at the workpiece. This leads to deeper penetration compared to DCEP (Direct Current Electrode Positive), where the electrons flow from the workpiece to the electrode.

Bead Shape

DCEN produces a narrower and deeper weld bead due to the concentrated heat at the workpiece. In contrast, DCEP creates a wider and shallower bead as the heat is more dispersed.

Spatter

DCEN generates more spatter than DCEP because the electrons are emitted from the electrode, causing metal droplets to be ejected from the weld pool. DCEP, with electrons flowing from the workpiece, results in less spatter.

Choosing the Right Polarity for TIG Welding: What Polarity Is Tig Welding

Selecting the appropriate polarity for TIG welding is crucial for achieving optimal weld quality and performance. Various factors influence the choice of polarity, including material thickness, joint type, and desired weld characteristics.

When welding thin materials, direct current electrode negative (DCEN) polarity is generally preferred. This polarity concentrates the heat on the workpiece, resulting in a narrower weld bead and less heat distortion. For thicker materials, alternating current (AC) polarity is often used.

AC polarity alternates the polarity of the electrode, allowing for deeper penetration and a wider weld bead.

Joint Type, What polarity is tig welding

The type of joint also influences the choice of polarity. For butt joints, where the edges of the materials are joined together, DCEN polarity is typically used. This polarity helps to focus the heat and create a strong, narrow weld bead.

For edge joints, where the edges of the materials are overlapped, AC polarity is often preferred. AC polarity allows for better penetration and fusion of the overlapped edges.

Desired Weld Characteristics

The desired weld characteristics also play a role in selecting the polarity. For welds requiring high strength and toughness, DCEN polarity is generally preferred. This polarity produces a narrower weld bead with less heat distortion, resulting in stronger welds. For welds requiring a wider weld bead and deeper penetration, AC polarity is often used.

AC polarity allows for a wider weld bead and better penetration, which can be beneficial for certain applications.

Applications of TIG Welding with Different Polarities

TIG welding with different polarities has various applications, each suited to specific requirements. Understanding the effects of polarity allows welders to optimize weld quality and efficiency.

Direct Current Electrode Negative (DCEN)

Thin Materials

DCEN is preferred for welding thin materials as it generates a focused arc that minimizes heat input, reducing the risk of burn-through.

Aluminum Welding

DCEN is commonly used for welding aluminum due to its ability to create a stable oxide layer on the weld surface, improving weld quality and strength.

Direct Current Electrode Positive (DCEP)

Thick Materials

DCEP is suitable for welding thick materials as it produces a broader, more penetrating arc, allowing for deeper weld penetration.

Stainless Steel Welding

DCEP is often used for welding stainless steel as it helps prevent carbide precipitation, which can weaken the weld.

Arc Gouging

DCEP is employed in arc gouging, a process that removes material by melting and blowing it away, due to its high arc energy and penetration.

Alternating Current (AC)

Versatile Applications

AC is versatile and can be used for welding various metals, including aluminum, steel, and titanium.

Square Wave AC

Square wave AC provides increased arc stability and penetration, making it suitable for welding thicker materials.

Balanced Wave AC

Balanced wave AC offers a compromise between DCEN and DCEP, providing a balance of penetration and surface cleaning.

Commonly Asked Questions

What is the difference between DCEN and DCEP in TIG welding?

In DCEN (direct current electrode negative), the workpiece is positively charged, while the electrode is negatively charged. This polarity results in deeper penetration and a narrower weld bead. Conversely, in DCEP (direct current electrode positive), the workpiece is negatively charged, and the electrode is positively charged, leading to shallower penetration and a wider weld bead.

How does polarity affect spatter in TIG welding?

DCEN polarity generally produces less spatter than DCEP polarity. This is because the negative charge on the workpiece attracts positively charged ions in the weld pool, reducing the amount of spatter ejected from the weld.

What polarity is best for welding thin metals in TIG welding?

DCEN polarity is typically preferred for welding thin metals in TIG welding. The deeper penetration achieved with DCEN helps to prevent burn-through and ensures a strong, reliable weld.